F-MARK2 Automatic Sheet Feeder Unit

High Volume Sheet Feeding and Cutting Unit

It can handle up to 200 sheets (depend on the thickness) of media in a continuous cycle but with the ability to add further sheets as required without interrupting the cutting process. This is a capability that sets the F-Mark2 Automatic Sheet Feeder Unit apart from any comparable sheet-fed system.

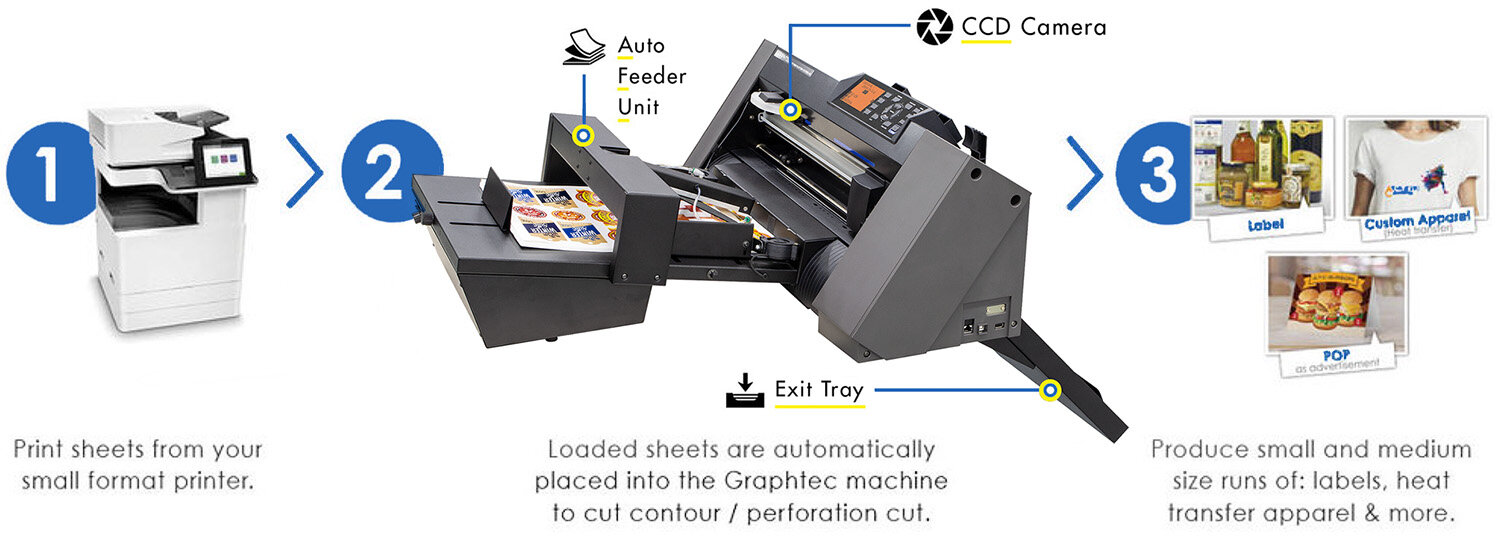

450 Grams of down force enable users to produce small and medium size runs of: labels, business cards, heat transfer apparel, and more. Using Adobe Illustrator and CorelDraw EPS file types, simply add registration marks to your design and import to the iMark Plus Software for fast, high quality results.

Cut labels and cut time with the new Graphtec F-MARK2 Automatic Sheet Feeder Unit.

• Continuous, HAND-FREE sheet media loading & processing

• Dedicated software ensures ACCURATE alignment

• CCD CAMERA quickly scans 2-point registration marks

• CONTOUR AND PERFORATED CUTTING of printed graphics

• Add additional sheets to the feeder WITHOUT RESENDING the job

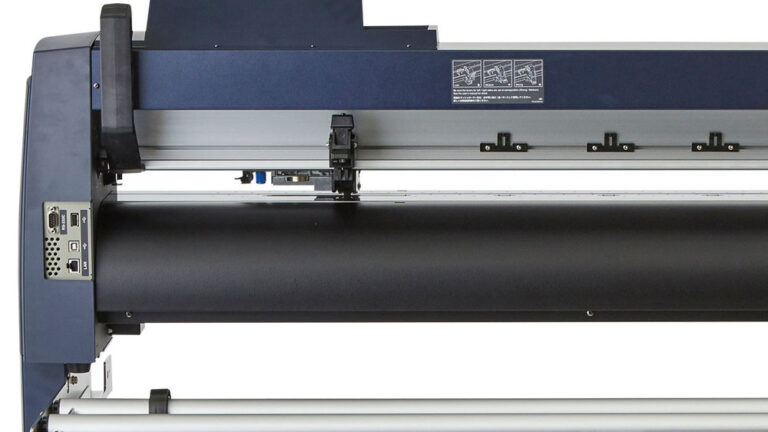

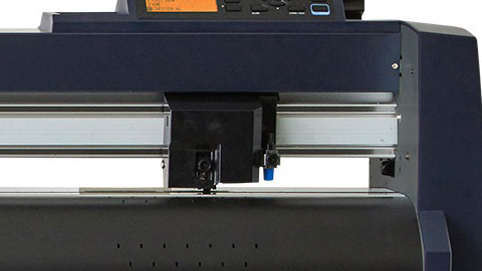

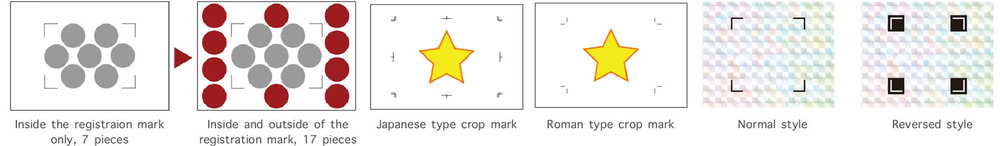

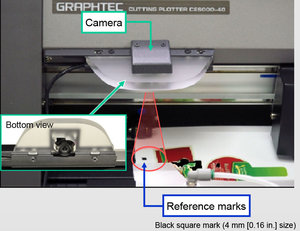

The Graphtec F-Mark2 Automatic Sheet Feeder Unit includes the CE7000-40 and is designed to automatically feed and contour cut media size up to 13″ x 19″ without the need for an operator. Equipped with precision iMark CCD camera technology the CCD camera allows for quick reading of crop marks with a precision grade of 0.2 mm.

It can handle up to 200 sheets (depending on the thickness) of media in a continuous cycle, but with the ability to add further sheets as required without interrupting the cutting process.

This is a capability that sets the Graphtec F-Mark2 Automatic Sheet Feeder apart from any comparable sheet-fed system.

INCREASE PRODUCTION EFFICIENCY BY AUTOMATIC RELOADING

The auto sheet feeder reloads the media to the cutting plotter automatically. The cutting process is executed repeatedly with replacing the media. It enables to significantly improve productivity in cutting a large number of media with the same patterns. The following steps are automatically repeated continuity until specified number of copies are made.

HANDS-FREE MEDIA LOADING

DETECTING MARKS

COUNTOUR CUTTING

MEDIA EJECTION

PERFECT SHEET ALIGNMENT

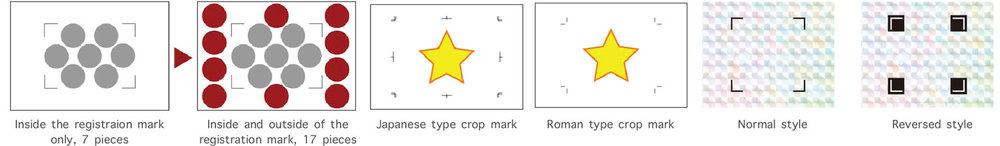

Perfect sheet alignment is achieved via crop mark reading for each individual sheet, with a camera equipped with Automatic Sheet Cutter technology performing the crop mark adjustments in a fraction of a second. Software algorithms compensate for any distortion from the printing process to enable precise cutting with minimal bleed. There is also an option to add perforated cut lines to your design during file creation.

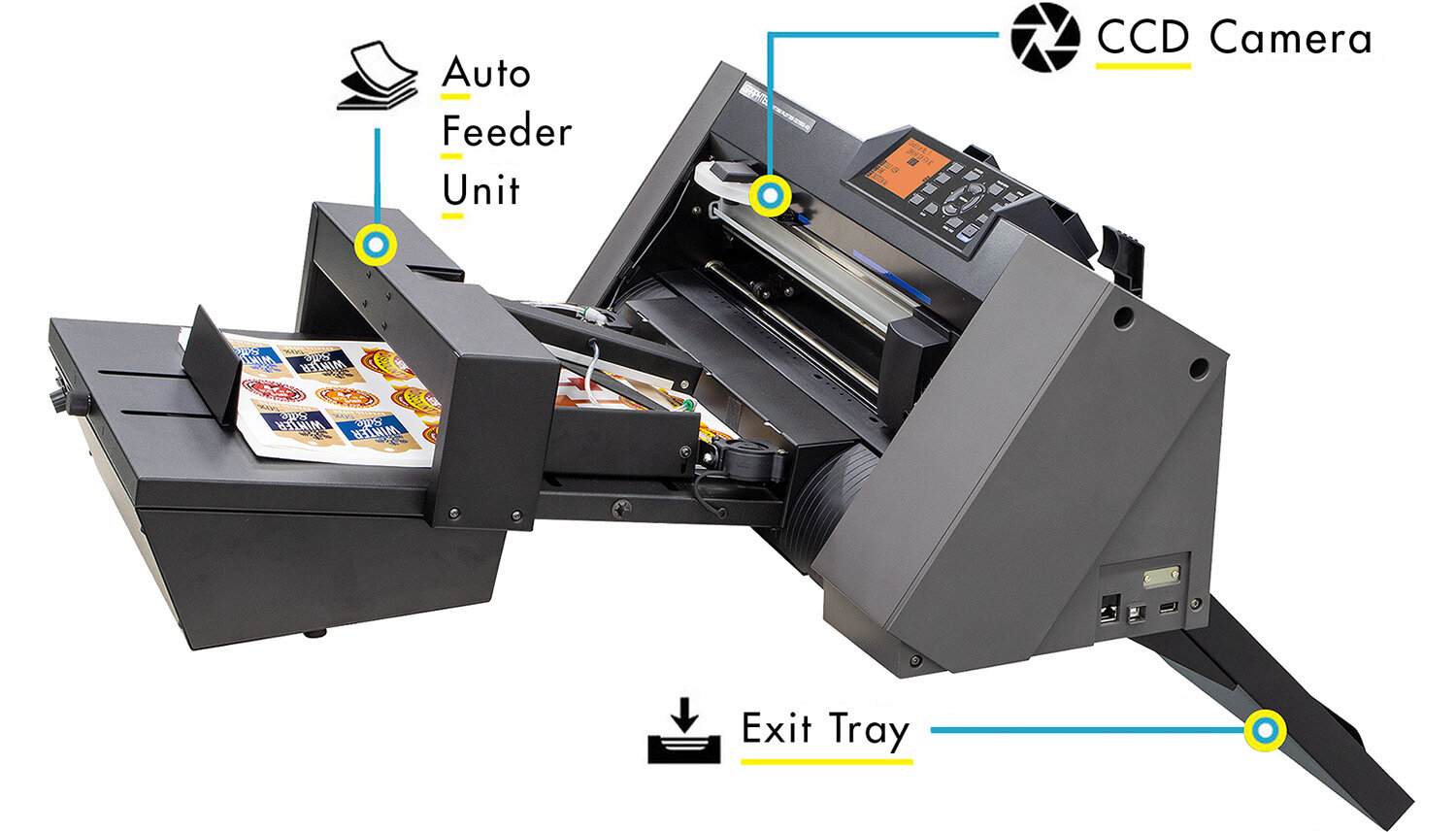

AUTO SHEET FEEDER UNIT

An arm with air suction cups lifts the media from the supply tray and places it into the cutter.

It is able to place the sheet media including 8.5” x 11” to 13” x 19” and its equivalent in the supply tray. It is able to stack up to 200 sheets of media or up to 1.4” high on the media supply tray. (Number of sheet varies by the material, thickness and condition of media)

EXIT TRAY

After cutting is completed, sheets are automatically placed in the tray.

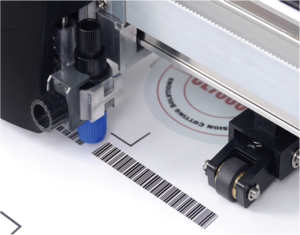

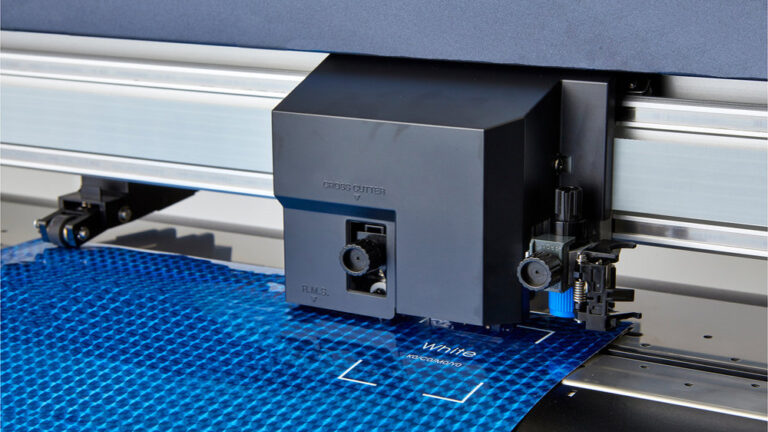

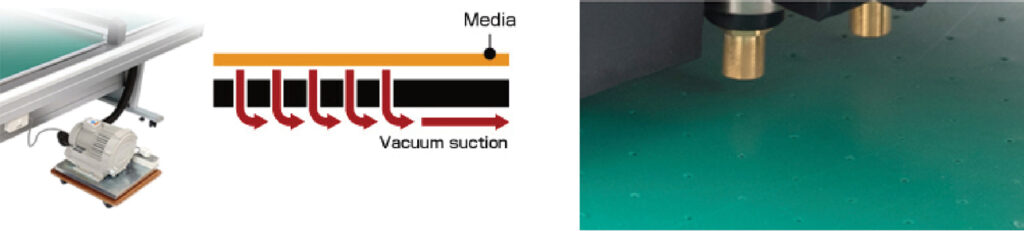

CCD CAMERA

Quickly detects 2-point reference marks for aligning the contour & printed images by the camera that is mounted on the top cover of the cutting plotter. The contour cutting is able to perform with selected cutting method such as the half cuts, perforation cuts, dashed-line cuts and special cutting emulated crease. It enables to expand the type of products can be produced by supporting multiple cutting method.

The position of contour cutting line is adjusted in the dedicated software using the detected reference marks. The ARMS (Advanced Registration Mark Sensing system) on the cutting plotter is not used for aligning the contour.

– The location of two reference marks as the solid square mark are located the left side of media.

– It is able to match the contour cutting to printed image even if printed images has the trapezoidal distortion.

The reference marks are detected quickly by the camera that is mounted on the cutting plotter.

– The mark sensor on the cutting plotter is not used.

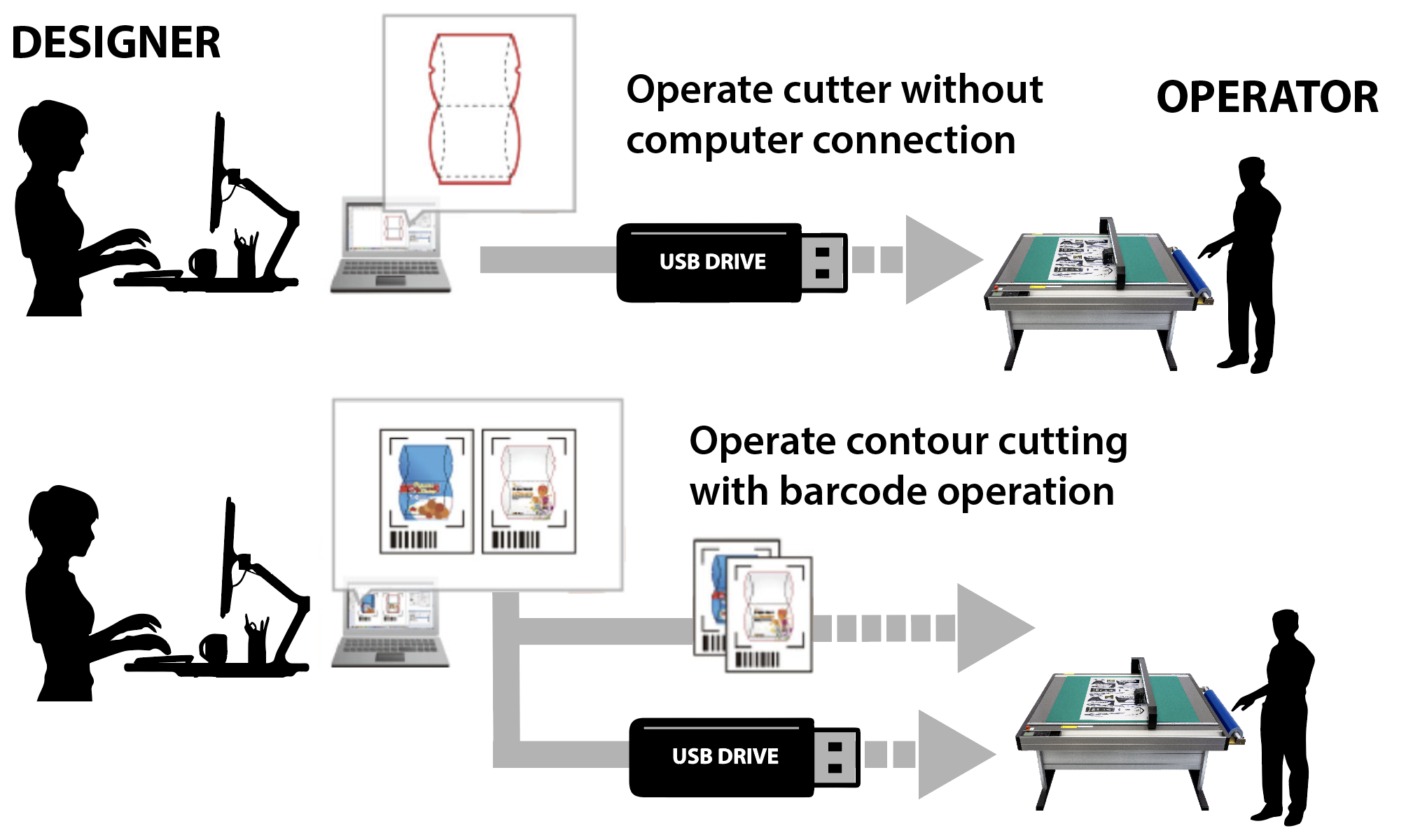

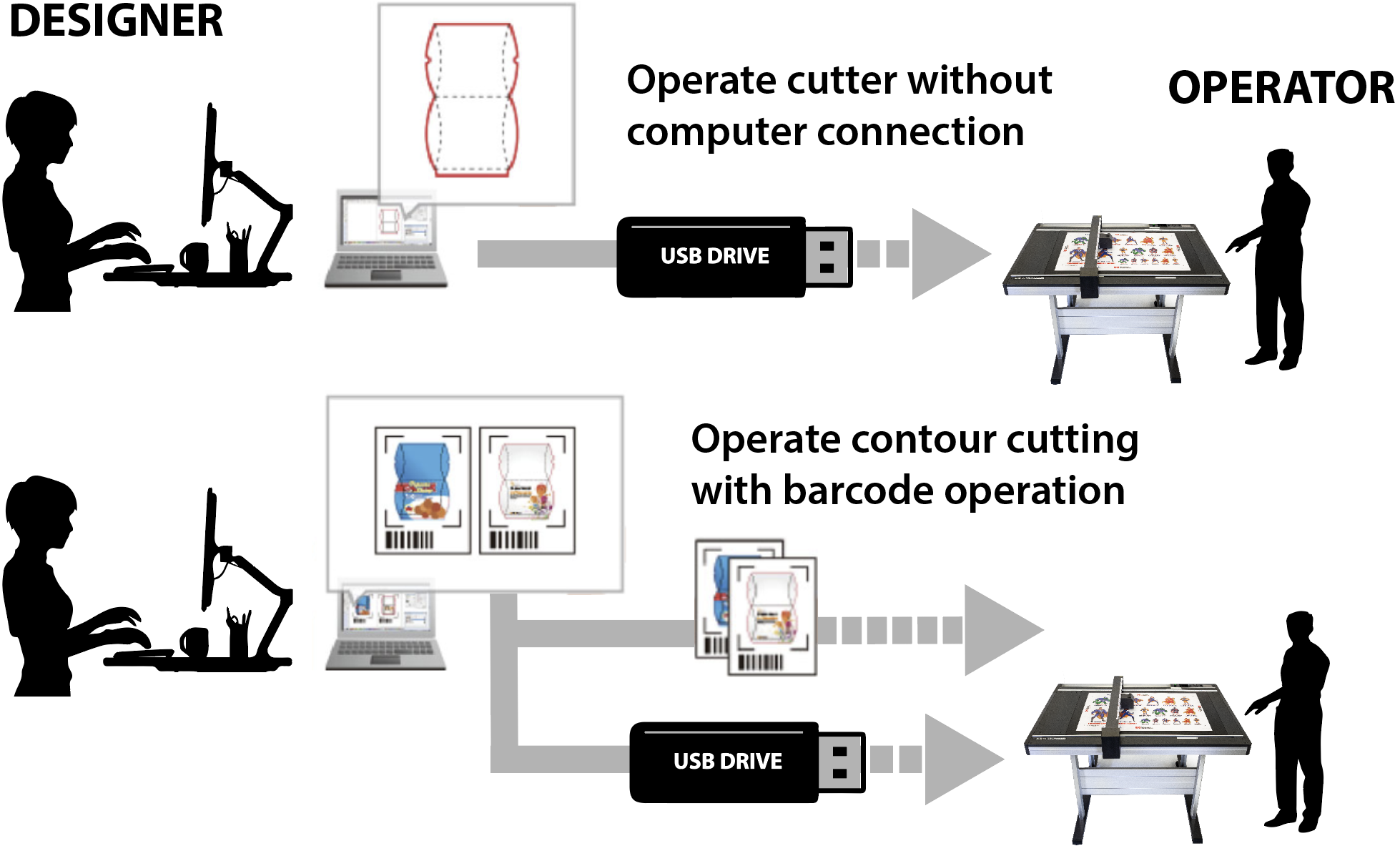

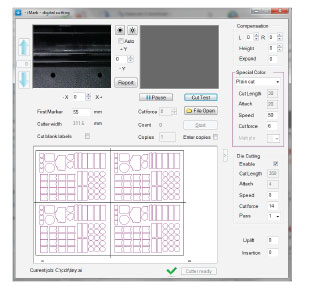

DIGITAL CUTTING SOFTWARE (FOR WINDOWS)

Dedicated software controls the auto sheet feeding system and transfers contour cutting data to the plotter.

The system includes dedicated application software. After media is loaded, the attached camera quickly detects 2-point reference marks and corrects alignment before contour cutting data is transferred, giving you the perfect cut every time. The software configures cutting conditions such as number of copies, cutting force, cutting speed, offset, and number of paths, and it can import Adobe Illustrator or CorelDRAW EPS files as the contour data.

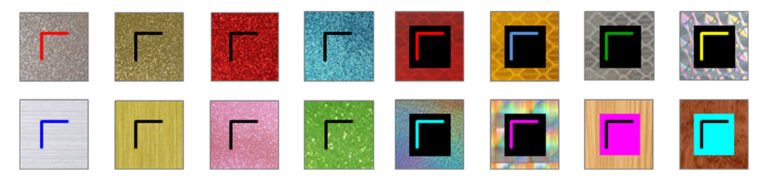

CUTTING METHODS

Looking for quality vinyl cutter machine or label cutter machine, or signage cutter machine, Graphtec is the ultimate time and effort saving label cutter, signage cutter that can help your vinyl cutting purpose become an easy process. Graphtec glob…

Looking for quality vinyl cutter machine or label cutter machine, or signage cutter machine, Graphtec is the ultimate time and effort saving label cutter, signage cutter that can help your vinyl cutting purpose become an easy process. Graphtec glob…

HALF-CUTS (PLAIN CUT)

The magenta line is cut with the half cut method. The speed and cut force can be set. It is useful for creating a set of labels including different shapes. It is used with the die cut. The magenta line will be executed in half-cut as the contour of each label. Other color line is executed with the perforation cut as a line for separating to sheet contained a set of labels. It is shown in the preview window on the right screen copy.

Effective for cutting the media for labels, the heat transfer sheet, and others. The half cut works to cut only the upper layer of the media.

The paper or vinyl media that have release sheet (liner) is used.

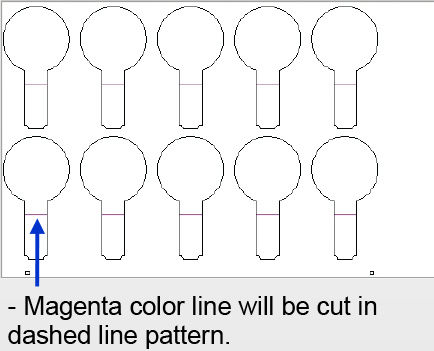

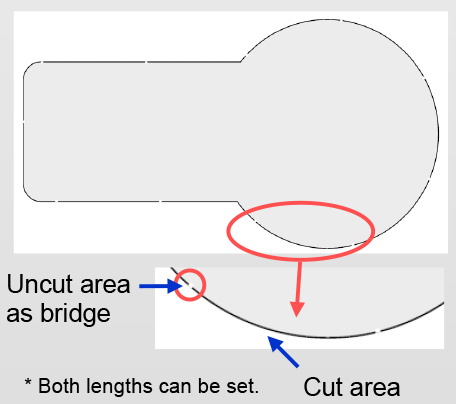

DASHED-LINE CUTS

Effective for creating the label, the dashed line cut works as to easily tear the sealing label of the bottle when opening. Also effective for creating POP signage. The dashed line cut works as folding line.

The magenta line is cut with the dashed line pattern. The length of cut and space of uncut can be set. It is useful for creating a tear line on the label such as the label to stick on lid of the bottle. It is shown in the preview window on the right screen copy. When it is used as the die cut to create the packing box, the line will be used for folding. It is shown in the preview window on the above screen copy.

PERFORATION CUTS

Effective for cutting the media for labels, POP signage, paper containers, and others. The cutting is executed with perforation pattern and works as a die cut for outline of shape or separator of label group.

EMULATING CREASING (BLADE CREASING)

The magenta line is cut by the blade with the special method to emulate the crease line. Cutting is performed on the backside of media. The speed, cut force, number of multiple line and spacing of multiple line can be set. It is useful for creating the package box when using with the die cut. The media is set printed side facing down on the media supply tray. Then, the process is performed from reverse side so the reference mark is not printed.

The position of first reference mark is set on the software, and alignment is done without detecting the reference mark by the camera.

Effective for creating the paper container box, the special cutting line works as the crease lines.- The outline of box is cut with perforation cutting.

The plain paper that does not have release sheet (liner) is used.

| Unit | Description | |

|---|---|---|

| Whole System | Supported standard sized media | 8.5″ x 11″ |

| Interface to PC | Single port of USB (The USB hub to connect the auto feeder unit and cutter unit is included.) | |

| Power source | 100 to 240 V AC (required three power outlets) | |

| Operating environment | Temperature: 50 to 95 ºF, Humidity: 35 to 75 % RH (non-condensing) | |

| Size | When the entire system is installed on a table – Size of portion above desk: approx. W 30.4” x D 32.25” x H 12.3” – Size of portion below desk: approx. W 30.4” x D 15” x H 16.5” * The CE7000-40 is placed on the edge of the table. Refer to the illustration. | |

| Weight | Approx. 55 lb (25 kg) | |

| Auto Feeder Unit | Supported Media | Width: 10.63″ to 13.78″, Length: 8.27″ to 19.69″ Width: 270 to 350 mm, Length: 210 to 500 mm Up to 350 g/m2 |

| Capacity of Exit Tray | Up to 200 sheets or up to 1.37 in (35mm) height (varies by the material, thickness, and condition of media) | |

| Interface | USB 2.0 | |

| Power Source | AC adapter, 100 – 240 V AC, approx. 60 VA at output power | |

| Digital Cutting Software | Supported OS | Windows 10, 8.1, 8, 7 |

| Contour cutting data format | Ai (saved as Ai 8) and EPS | |

| Cutter Unit | Cutting Speed | Max. 600mm/s 24” ips in all directions |

| Acceleration | Max. 69 ft 6.64 in/s2 (21.2 m/s2) (2.2 G) at 45º direction | |

| Cutting force | Max. 4.41 N (450 gf) with CE7000-40 | |

| Compatible Stardards | UL, cUL, CE mark, RoHS Directive | |

| Power Source | 100 – 240 V AC | |

| Power Consumption | Max. 120 VA | |

| Warranty | Standard | 2 YEAR |

10% OFF

GRAPHTEC ACCESSORIES

when you register any Graphtech Cutter.

Contact us for more details.